We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

If you’re passionate about metal cutting or just keen to learn more, you’ve landed in the right place.

For over 38 years, Amber Steel has been at the forefront of metal cutting services, specializing in laser cutting, flame cutting, and plasma cutting. Our expertise has carved a niche in this cutting-edge industry, delivering precision and excellence across industrial projects big and small.

In our blog, we’ll share a mix of useful tips, innovative applications, our thoughts on sustainability in steel cutting, and more. Expect stories from the cutting floor, insights into how our processes can streamline projects across industries, and a few lessons we’ve learned along the way.

While we keep some of our trade secrets under wraps, this blog is designed to offer valuable nuggets of wisdom that you simply won't find anywhere else. Whether you’re a professional in the industry or someone fascinated by the possibilities of metal cutting, you'll find something of value here.

So, stick with us as we delve into the finer points of metal work. We’re glad to share our insights and lead discussions that matter to our industry.

How precision metal cutting propels the aerospace industry, from constructing lighter frames to enhancing aerodynamics.

The role of advanced metal cutting in automotive manufacturing, driving innovations in vehicle design and efficiency.

All about the robust and versatile process of flame cutting, ideal for tackling thicker metals with precision and ease.

Discover the art of crafting metal furniture, where cutting techniques meet design to create both functional and aesthetic pieces.

A behind-the-scenes look at the mechanics of metal cutting technologies and the science that makes them tick.

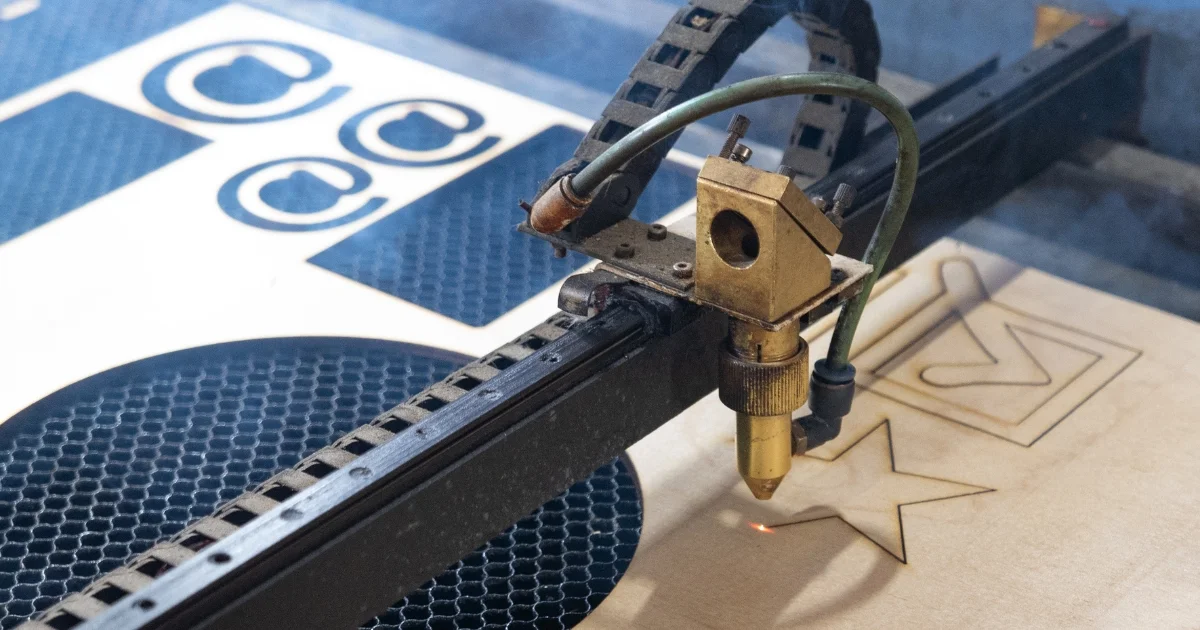

Laser cutting is where extreme precision meets efficiency, allowing for intricate designs and clean finishes.

The critical role of precise steel cutting in developing reliable and intricate medical devices.

How steel cutting supports the oil and gas industry with components that withstand extreme environments and pressures.

Known for its speed and versatility, plasma cutting slices through conductive metals with hot plasma.

Safety first! Tips and insights on maintaining a safe environment while handling powerful metal cutting equipment.

The backbone of construction, where steel fabrication and cutting technologies create frameworks that shape skylines.

Sustainability

A look at sustainability in metal cutting, focusing on practices that reduce waste and conserve energy to protect our planet.

In fabrication, the true cost of a mistake doesn’t always show up right away. A slightly uneven kerf or a cut edge just a bit off might seem minor, but once that part reaches assembly, the problem often grows.

Suddenly, you’re facing delays, rework, or even scrapped components. These aren’t small issues—they waste time, raise material costs, and disrupt every phase that follows. That’s why precision cutting matters.

When cuts are clean and consistent from the start, the rest of the process runs more smoothly. Parts fit the way they should, operators spend less time fixing mistakes, and timelines are easier to keep. Fewer surprises means fewer setbacks.

Smooth production helps avoid the ripple effect of delays that creep into forming, welding, finishing, or final assembly. The result is better labour efficiency, tighter cost control, and more predictable outcomes.

Rework doesn’t just add a few minutes—it sets off a chain reaction. A slightly off-spec part might need grinding, welding, or machining just to be usable. That pulls workers off primary tasks, delays other jobs, and consumes more material than expected.

These disruptions rarely happen in isolation. When parts don’t fit, production lines stall. Project managers scramble to adjust schedules or even halt assembly until replacements are cut. A single error quickly multiplies across the job.

For manufacturers, these fixes quietly reduce margins. They stretch timelines, use up labour, and sometimes lead to missed deliveries or rejected parts. It also affects morale, with skilled workers stuck fixing avoidable mistakes. Instead of building, they end up correcting.

That’s why more fabricators are making cutting accuracy a priority. Reducing variation at the start helps eliminate issues later. It’s a simple equation: better cuts lead to fewer problems.

Precision cutting isn’t just about having better equipment. It’s about using that equipment with accuracy and consistency. Standard machines can get the job done, but they often introduce variation. A slight burr, a wider kerf, or a misaligned feature can be enough to throw a part out of spec.

Precision setups minimize that risk. Whether it’s laser, plasma, or waterjet, the goal is consistent accuracy. These machines are calibrated to hold tight tolerances across both simple and complex cuts, even through long production runs.

That’s where the benefits add up. Clean edges, minimal burrs, and precise hole placement reduce scrap and simplify the next step. When parts move smoothly into welding, forming, or assembly, production stays on track.

Take a steel bracket headed for welding. If the holes are even slightly off, extra grinding or clamping might be needed just to make it fit. With precision cutting, that bracket arrives accurate and ready to install.

It’s not just about edge quality. It’s about cutting risk, saving time, and keeping the entire process moving efficiently.

When a part isn’t cut correctly, it sets off a chain reaction. Assembly slows down, welding becomes more difficult, and quality control ends up flagging issues that could have been avoided. Small errors early on can ripple through the entire job.

Cutting parts to spec from the beginning helps everything fit as intended. Welders focus on their actual work instead of fixing flaws. Assemblers spend less time realigning components. Teams avoid last-minute adjustments that throw off the schedule.

Precision cutting also makes the workspace safer. When operators don’t have to grind or fix edges, they’re exposed to fewer hazards like sparks, debris, and repetitive motion strain.

Material handling becomes easier, too. Clean, accurate cuts reduce sharp edges and help prevent warping, making parts safer to move through forming or finishing without damage. In short, better cuts lead to better flow.

It’s like building on a solid foundation. When the base is level and true, every step that follows runs more smoothly. Precision cutting sets that foundation from the very first move.

Choosing the right cutting process isn’t just about preference. It’s about matching the method to the performance requirements of the job.

Laser cutting delivers exceptional precision with clean lines and tight tolerances. It’s especially valuable for thin to medium materials used in industries like aerospace and medical devices, where consistency and edge quality are critical. With heat-affected zones as small as 0.1mm and tolerances down to ±0.003", laser systems provide excellent control for complex parts.

Plasma cutting is ideal when speed and cost-effectiveness are priorities. It works well with medium to thick materials, up to 1.250", commonly used in construction, mining equipment, and industrial machinery. Modern high-definition systems can hold tolerances around ±0.040", making plasma a strong choice for large-scale projects that demand both speed and accuracy.

Flame cutting remains the most practical option for very thick steel plate, from 2" up to 12". It’s commonly used for structural steel, shipbuilding, and oil and gas components. Although the heat-affected zone is wider than with other methods, careful control helps maintain cut quality and reduce distortion, even on large profiles.

Each cutting method has specific advantages. The key is selecting the one that aligns with the material type, thickness, and overall fabrication goals.

It’s one thing to cut a part accurately. It’s another to design that part in a way that makes precise cutting possible in the first place.

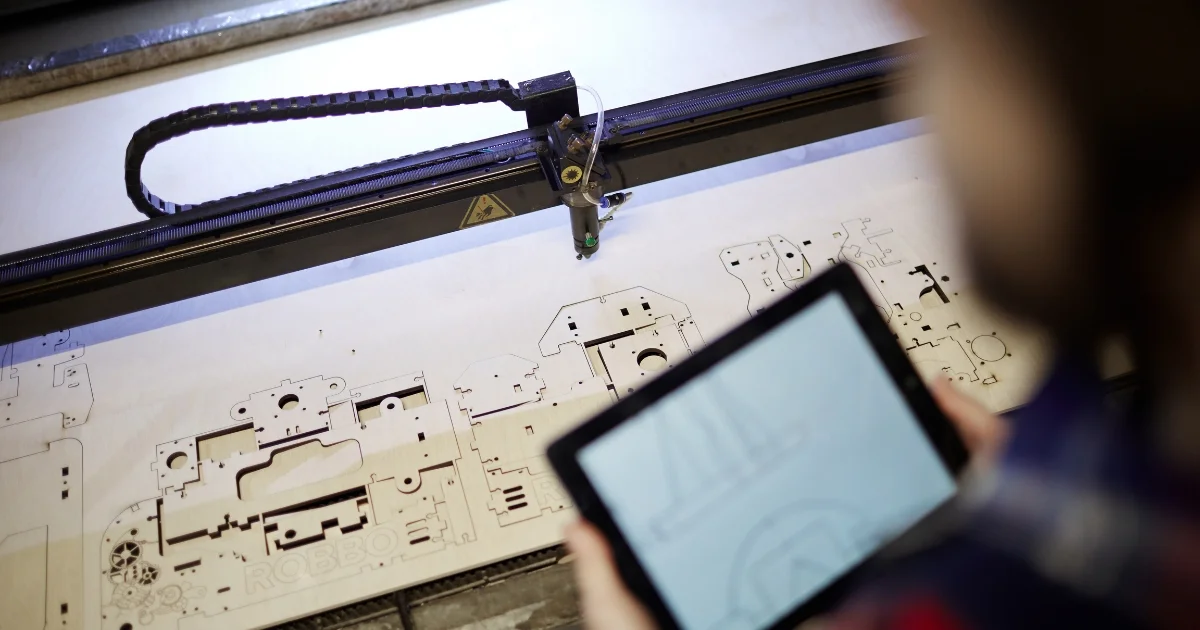

That’s where Design for Manufacturability (DFM) comes into play. When engineers plan for the cutting process from the start, instead of after the fact, it helps prevent the issues that often lead to delays or rework.

Here are a few simple but critical strategies:

Avoid tight internal corners that are difficult to machine or cut cleanly.

Space holes and features far enough apart to reduce the risk of distortion.

Account for kerf width, especially when transitioning between laser, plasma, or flame cutting methods.

Take a steel gusset plate, for example. A sharp 90-degree internal corner might seem like a clean solution on paper, but in reality, it creates stress concentrations and cutting challenges. Adding even a small radius, such as 0.125", can reduce risk and extend the lifespan of the part.

Today’s precision cutting is no longer just mechanical. It’s becoming increasingly intelligent. Modern monitoring systems now track cut quality in real time, alerting operators to potential issues like overheating, nozzle degradation, or inconsistent speeds. These alerts help catch problems early, before they impact entire production runs.

Artificial intelligence is taking this a step further. AI-driven platforms automatically adjust cutting parameters based on live data, fine-tuning speed, power, and gas pressure to maintain consistent quality, even when material properties fluctuate.

This kind of automation is especially valuable in high-stakes industries like aerospace, where even one rejected part can cost thousands. Manufacturers using AI-driven tools have seen up to 40% gains in overall efficiency, helping reduce delays, improve precision, and minimize costly errors.

And this technology is no longer reserved for large-scale operations. As prices fall and software improves, smaller fabrication shops are beginning to adopt these tools as well. The result is more consistent outcomes and fewer production issues—without the need for oversized budgets or dedicated automation teams.

Not every part demands ultra-tight tolerances, but when precision matters, there’s no substitute for a clean, accurate cut.

Precision cutting services are especially valuable in projects where:

The material is costly, rare, or difficult to replace

The part requires tight fit-up or minimal weld prep

The application involves regulated standards or traceability

The timeline is tight, and mistakes come with high penalties

Industries like defense, electronics, medical, and transportation often fall into this category. In these environments, even a small dimensional error can cause major setbacks—or worse, complete part rejection.

Precision cutting helps eliminate that risk. It improves part quality, reduces scrap, and keeps teams focused on progress rather than corrections. When you know your parts will arrive ready to assemble, there’s no need to pad your schedule or overcompensate in later stages. You can move forward with confidence.

When the cost of a bad part is high, a well-cut one becomes far more than a line item. In these cases, precision is not an upgrade—it’s a requirement.

Cutting may happen early in fabrication, but it affects every step that follows. If the cut is off, delays spread quickly. If it’s clean and accurate, the rest of the job stays on track.

That’s why cutting accuracy is one of the smartest places to invest. It reduces downstream problems, protects your schedule, and keeps production focused on building—not correcting mistakes.

In high-pressure environments with tight deadlines, costly materials, or complex assemblies, there’s no room for error. Precision cutting services from the start help prevent problems before they begin.

Need precision without the rework? Contact us to request a quote or talk to a fabrication expert about your next project. Our team delivers clean, consistent cuts tailored to your specs—every time.

Ever seen a production line stop because parts don't fit together? Metal shops face this problem daily when bad cuts cause problems throughout manufacturing. Rough edges from old cutting methods force welders to spend hours grinding and prepping, while poor material use wastes up to 15% of expensive steel plate.

These aren't just cutting station issues—they're factory nightmares that delay shipping, waste money, and frustrate everyone from shop floor to front office. Plasma cutting steps in as the hero, delivering clean edges, tight tolerances, and consistent results that turn production bottlenecks into smooth operations.

Let's explore how smart plasma cutting doesn't just improve one step but transforms the entire production flow. When your first manufacturing step hits the mark, everything after gets easier, faster, and more profitable.

Plasma cutting works like a super-blowtorch. It turns regular compressed gas into a superheated electrical conductor reaching over 30,000°F. That's hot enough to melt steel instantly while a high-pressure gas stream blows the molten metal away. This creates a clean, narrow kerf with minimal heat-affected zone (HAZ), keeping the material's properties intact around the cut.

Today's CNC plasma systems keep exact torch height and cutting settings that deliver tolerances as tight as ±0.040". It's like starting a trip with perfect tire alignment. Small errors at the start cause big problems later, while starting right means smooth going the whole way.

In real shops, plasma cutting isn't just another step. It's the first domino that affects everything after:

Material prep and nesting

Plasma cutting

Edge cleaning and conditioning

Forming operations

Machining and feature addition

Welding and assembly

Surface treatment and finishing

Quality inspection and shipping

Each of these steps relies on accuracy from the cut. Material prep is easier when nesting is optimized, and sheets are labelled clearly. Edge cleaning is often reduced or eliminated, saving hours of labour per project. Even final inspection and shipping benefit when every part fits and meets spec without the need for extra rework.

Plasma cutting doesn’t just improve individual steps—it enables a more efficient, connected production line. By reducing manual intervention, rework, and misalignment, it supports lean manufacturing goals like improved cycle times and reduced waste. These small gains add up to major operational advantages over time.

Try folding paper with ragged edges and you'll never get clean, even results. The same idea applies when forming plasma-cut parts. The controlled heat from modern plasma systems means press brake operators spend less time fighting material and more time making good bends.

The reduced heat-affected zone means less hardening near cut edges, making metal forming more predictable and cutting down on cracks during bending. With 12-foot presses at 250-ton and 150-ton capacities, forming operations can fully use the consistency of plasma-cut parts. This improvement turns forming from a bottleneck into a reliable operation.

Shop managers often name welding problems as their biggest headaches. Quality plasma cutting tackles this issue at the source:

Fit-up becomes simple: Parts line up naturally, cutting down setup time and clamp adjustments.

Filler material usage drops: Tight-fitting joints need less weld material.

Defects become rare: Clean edges without slag make stronger, more consistent welds.

Welders work faster: Good joint prep lets welders keep higher travel speeds and focus on quality.

CWB-certified welding operations especially benefit from plasma-cut components, as they reduce factors that can cause weld defects. With Flux Core & Hard Wire MIG stations set up for hot-rolled steel, the precision from upstream plasma cutting creates major efficiency gains throughout welding.

When plasma-cut parts move to machining centres, accuracy reduces setup time and material waste. Tools last longer, and cycles run faster thanks to less excess stock.

With machining centres like the Haas VF6 and VF4, starting with clean plasma-cut blanks supports precision workflows, especially in aerospace.

Modern plasma systems aren't one-size-fits-all. They offer multiple cutting modes that smart shops use strategically:

Matching cutting settings to job requirements helps shops balance speed and edge quality—especially with large-format or thick materials.

Different materials react uniquely to plasma cutting, creating downstream handling issues:

Carbon steel: Cuts clean with minimal oxidation, usually ready for immediate processing.

Stainless steel: Needs special gas mixtures to prevent nitride formation that might harm corrosion resistance.

Aluminum: Benefits from high travel speeds that minimize heat distortion in thinner sections.

Smart shops plan their production flow with these material behaviours in mind. With material thickness ranges from 0.5mm to 25.4mm for various metals, production planning must account for these material-specific responses to plasma cutting. This material-specific thinking raises overall manufacturing quality.

Modern plasma systems don't work alone. They're connected parts in increasingly digital production settings:

Shared programming data: Cutting paths can inform downstream CNC operations, ensuring consistency.

AI-powered nesting: Advanced software reduces waste while organizing parts for efficient sorting.

Real-time production metrics: Cut times and material usage feed back into ERP systems for accurate costing.

These connections allow shops to monitor actual vs. expected cut times, adjust future quotes, and track material yield per job. For example, when a system logs real-time cut efficiency, it helps identify bottlenecks early and avoid excess inventory orders. That means tighter control over timelines and more accurate job costing.

With ERMAKSAN ER99 2D/3D programming capabilities, CNC plasma cutting systems become a central hub in the digital manufacturing workflow. This digital integration transforms plasma cutting from a standalone process into a connected manufacturing intelligence centre.

Plasma cutting's consistency opens doors to automation throughout production:

Robotic material handling becomes feasible: Predictable dimensions enable automated transfers between stations.

Automated inspection saves time: Vision systems can quickly check parts against specifications.

Manufacturing cells run smoothly: Cutting, bending, and welding can operate as integrated units when part consistency is high.

Medical device manufacturers particularly benefit from these capabilities. With tight tolerances of ±0.040", plasma cutting creates parts consistent enough to enable downstream automation that maintains high precision while reducing labour costs compared to manual processes.

The automotive industry's constant push for efficiency makes it perfect for showing plasma cutting's downstream benefits:

Assembly becomes predictable: Components fit together right the first time on production lines.

Safety-critical welds perform better: Consistent connections improve structural integrity during crash testing.

Material utilization improves: Precision cutting enables optimized designs that save weight without losing strength.

Common plasma-cut parts include engine brackets, crash structure supports, seat frames, and underbody reinforcements. When these components start with accurate geometry and clean edges, secondary processes like robotic welding and hydroforming produce better final results. The precision of the initial cut is what allows modern vehicles to be lighter without sacrificing safety or durability.

With automotive applications ranging from custom parts for panels and chassis to structural steel components, plasma cutting's mix of speed, quality, and flexibility makes it increasingly valuable to automotive suppliers competing for advantage.

For manufacturers building rock crushers, excavator components, and other mining equipment, plasma cutting's ability to handle thick plate (up to 1.250") delivers major benefits:

Grinding time plummets: What once took hours of edge prep now needs minimal work.

Weld quality improves dramatically: Better edge preparation leads to stronger, more consistent connections.

Production throughput accelerates: When thick plate cutting no longer slows production, delivery times shrink.

These manufacturers especially appreciate plasma's balanced approach, offering durability, thickness handling, and fast fabrication for mining components where material strength and production speed are critical factors.

The economic benefits of plasma cutting efficiency ripple through the entire production system. Reduced material waste from optimized nesting can save 10–15% on raw material costs, especially when advanced software is used. By minimizing rework and streamlining fit-up, shops can also reclaim valuable labour hours and speed up production timelines.

Plasma cutting supports sustainability through cleaner gas use, lower emissions, and energy-efficient operation. It also improves shop safety by reducing sharp burrs and minimizing manual grinding. Fewer injuries and a cleaner workspace help boost long-term productivity.

Plasma cutting isn’t just a process improvement. It’s the starting point for better manufacturing. Clean cuts and tight tolerances reduce rework, improve fit-up, and keep every step that follows on track.

Old cutting methods slow everything. Rough edges cause assembly issues, more scrap, and wasted time. In modern fabrication, precise cutting is essential.

As demands rise for speed and quality, plasma cutting offers real, measurable gains. When cutting is fully integrated into production, efficiency improves across the board.

Want to cut delays, reduce scrap, and keep jobs moving? Let’s talk about where better cutting can make the biggest impact.