We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

If you’re passionate about metal cutting or just keen to learn more, you’ve landed in the right place.

For over 38 years, Amber Steel has been at the forefront of metal cutting services, specializing in laser cutting, flame cutting, and plasma cutting. Our expertise has carved a niche in this cutting-edge industry, delivering precision and excellence across industrial projects big and small.

In our blog, we’ll share a mix of useful tips, innovative applications, our thoughts on sustainability in steel cutting, and more. Expect stories from the cutting floor, insights into how our processes can streamline projects across industries, and a few lessons we’ve learned along the way.

While we keep some of our trade secrets under wraps, this blog is designed to offer valuable nuggets of wisdom that you simply won't find anywhere else. Whether you’re a professional in the industry or someone fascinated by the possibilities of metal cutting, you'll find something of value here.

So, stick with us as we delve into the finer points of metal work. We’re glad to share our insights and lead discussions that matter to our industry.

How precision metal cutting propels the aerospace industry, from constructing lighter frames to enhancing aerodynamics.

The role of advanced metal cutting in automotive manufacturing, driving innovations in vehicle design and efficiency.

All about the robust and versatile process of flame cutting, ideal for tackling thicker metals with precision and ease.

Discover the art of crafting metal furniture, where cutting techniques meet design to create both functional and aesthetic pieces.

A behind-the-scenes look at the mechanics of metal cutting technologies and the science that makes them tick.

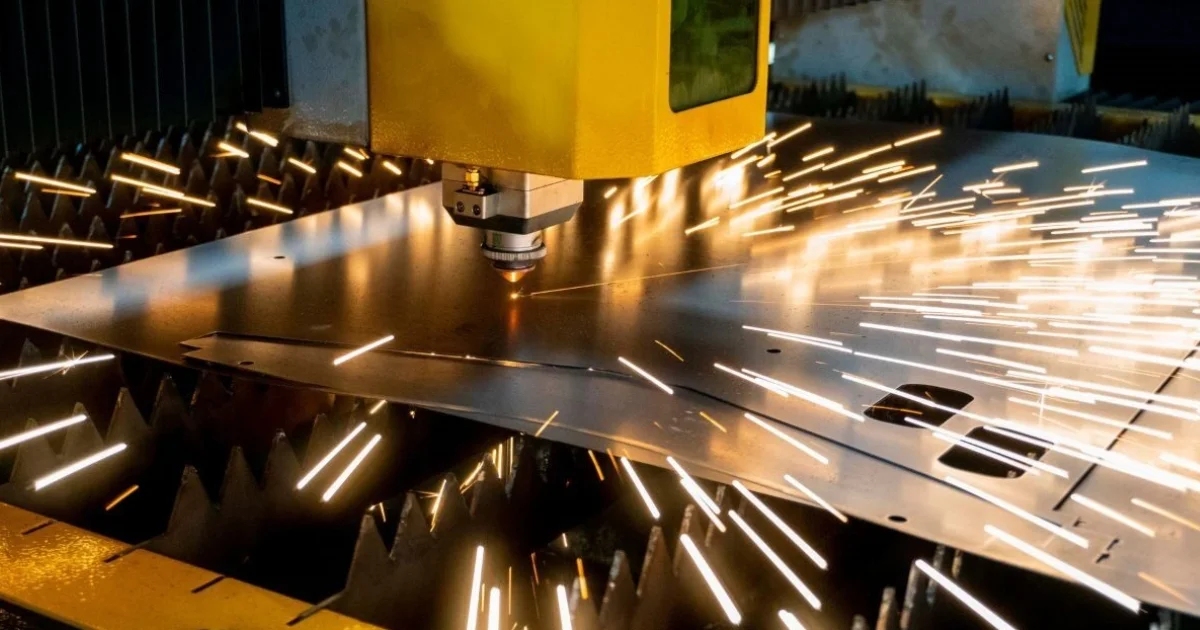

Laser cutting is where extreme precision meets efficiency, allowing for intricate designs and clean finishes.

The critical role of precise steel cutting in developing reliable and intricate medical devices.

How steel cutting supports the oil and gas industry with components that withstand extreme environments and pressures.

Known for its speed and versatility, plasma cutting slices through conductive metals with hot plasma.

Safety first! Tips and insights on maintaining a safe environment while handling powerful metal cutting equipment.

The backbone of construction, where steel fabrication and cutting technologies create frameworks that shape skylines.

Sustainability

A look at sustainability in metal cutting, focusing on practices that reduce waste and conserve energy to protect our planet.

One stalled part stops an entire assembly line. Automotive timelines are tight, and a single production delay can cascade into costly disruptions throughout the supply chain. As demand rebounds and EV production accelerates, OEMs and Tier 1 suppliers are under growing pressure to scale fast – without sacrificing quality or cost.

A McKinsey report explains that the shift to EVs adds even more pressure. Suppliers are now racing to meet demand while staying efficient and cost-conscious. When production bottlenecks hit, delays ripple through the supply chain, costing time, money, and trust at every level, from manufacturers to end users.

This is where plasma cutting for automotive manufacturing comes in—delivering fast, flexible throughput on thick steel components at scale. Whether it’s cutting structural steel for chassis reinforcements or brackets for assembly lines, plasma technology is made for scaling – and built for steel.

This post looks at how plasma cutting supports high-volume automotive production, when it’s the right choice, and why part accuracy, material range, and smart systems matter when selecting a service provider. You’ll also see how it stacks up against other cutting methods and fits into today’s fast-moving automotive workflows.

When production ramps up, your cutting process needs to keep up. Scaling up isn't just about producing more but about doing so without adding friction. As demand increases, manufacturers need systems that won’t slow under pressure or require costly rework.

Plasma cutting offers that rare combination of speed and repeatability while staying flexible enough to support ongoing design changes. It allows production lines to ramp up fast while maintaining part consistency across thousands of units. Plasma cutting is well-suited for high-demand automotive manufacturing because of its speed, power, and flexibility. It’s built to meet the needs of large-scale operations without slowing things down.

Plasma cutting stands out in several key areas for automotive use:

Cuts through thick materials (up to 1.250") often found in frames, underbodies, and structural parts

Runs at high speeds across large cutting beds (some as big as 12' x 63') to boost part output

Delivers precision within ±0.040", which works for most structural and semi-precision needs

Keeps cycle times steady with minimal tool wear, even in high-volume runs

Unlike laser cutting, which is ideal for thin metals or very detailed designs, plasma works best when you need strength, speed, and size. It’s a great fit for cutting structural steel and hot-rolled sheet stock that will feed directly into presses, weld cells, or frame assembly stations.

Plasma cutting is often seen as a cost-saving option. But with the right setup and equipment, it becomes a real asset for production – not just prototyping. Modern CNC plasma cutting transforms automotive workflows. These systems combine cutting, marking, and forming.

The result? Parts that arrive ready for assembly, such as:

Structural reinforcement panels

Engine and transmission brackets

Subframe connectors

Shielding and protective components

Chassis braces and cross-members

This flexibility is one reason plasma cutting for automotive manufacturing continues to gain traction in high-output production environments. It’s fast, adaptable, and precise hallmarks of reliable automotive manufacturing solutions.

Integrated workflows that include forming, machining, welding, and part marking are increasingly common in modern plasma cutting setups. This means parts come off the line ready to assemble – no need to send them out for extra steps.

That kind of integration saves time and cuts down delays. It also makes CNC plasma cutting a smart solution when production is growing fast and you need tools that can keep up.

Plasma cutting works across a wide range of metals and material sizes. This flexibility makes it a strong choice for manufacturers working across multiple platforms or material specs.

It can:

Cut carbon steel, stainless steel, and aluminum

Handle thicknesses from 0.25" to 1.250" with reliable edge quality

Maintain cut consistency across different grades without slowing down

Switch between stock sizes with minimal setup time

When your production needs vary by vehicle model or material type, this adaptability becomes a major advantage.

Smart software now plays a big role in boosting plasma cutting productivity, especially for automotive manufacturing. Modern systems use automation and data to improve precision, reduce waste, and keep production moving fast.

Today’s software helps lay out parts in smarter ways:

Tightly arranges parts to use more of each steel sheet

Cuts down on waste by placing parts in the best orientation

Maps cutting paths to reduce torch movement and save time

Recognizes shared edges between parts and cuts them together

This helps automotive suppliers get more parts per sheet and less scrap overall.

Automation also improves cutting performance during production:

Adjusts torch height and speed for better cut quality

Tracks wear on nozzles and electrodes for consistent results

Auto-corrects for material differences without pausing the job

Supports unmanned operation for longer production runs

These features reduce the need for manual checks and help keep parts uniform across large orders.

Pairing plasma cutting with forming software and part-marking tools streamlines production. This approach cuts, labels, and bends every part in one seamless process. It reduces handling time and integrates perfectly with lean manufacturing setups.

Even though plasma is a heat-based process, newer systems have made big gains in efficiency and sustainability. Many shops now follow zero-waste practices, recycling all offcuts and maximizing material use from the very first CAD file.

Modern plasma systems support cleaner, more responsible manufacturing:

They reduce waste using optimized nesting and shared cuts

They use less energy with inverter-based power supplies

They lower emissions by improving gas use and adding filtration

They manage water more efficiently in water table setups

Sustainability is no longer just a value add but, in many cases, a requirement. As OEMs publish ESG targets and seek greener partners, suppliers must show how they reduce waste, energy, and emissions. Plasma cutting systems that optimize nesting, minimize scrap, and support recycling deliver measurable impact.

These upgrades matter. As more OEMs aim to cut their carbon footprint, they look for suppliers who also care about environmental impact. Choosing cutting systems that prioritize sustainability helps suppliers align with OEM environmental targets and ESG standards.

Plasma cutting stands out across many automotive applications, especially in chassis systems, powertrain supports, and safety components. It’s often the best choice when production speed, part consistency, and material strength are top priorities.

Plasma cutting works well when part volumes increase quickly to meet production targets. It supports just-in-time delivery schedules with fast turnaround and dependable throughput. Thousands of parts can be produced with consistent quality across each run. Plus, manufacturers can scale output without needing major equipment upgrades.

If your components use thick steel plates, plasma cutting is often more effective than laser systems. It’s ideal when structural strength is non-negotiable or when you need to cut through materials thicker than what lasers can handle. Plasma also handles multiple material types on the same system without long setup changes.

For material-heavy jobs, it’s often the most cost-efficient option. Suppliers seeking thick steel cutting solutions turn to plasma for reliable throughput without high tooling costs.

Speed and efficiency matter, especially in fast-moving assembly environments. Plasma-cut parts often require little to no finishing before they move to the next step. When quality documentation and traceability are required, plasma systems with integrated marking make tracking easy.

Design changes are also easier to manage, thanks to the system’s flexibility.

With fast cutting speeds, large bed sizes, and tight integration into manufacturing workflows, plasma cutting helps keep production on schedule without causing downstream delays or bottlenecks.

Not all CNC plasma cutting services are created equal. Look for providers with automation, inspection, and support across the full production chain. Choosing the right plasma cutting provider for automotive work requires more than just fast equipment. The best partners bring a full set of capabilities that support production from start to finish.

Look for providers with:

Large cutting beds and strong material handling systems

Multi-torch setups to cut several parts at once

High-definition plasma for better edge quality

Integrated marking tools for part ID and traceability

Strong quality control includes:

In-process inspection and tracking

Material certification and traceability paperwork

Statistical process control for consistency

First article inspections and reporting

You’ll want a partner who can:

Handle spikes in volume without delay

Offer quick turn support for urgent needs

Adjust production schedules as things shift

Manage inventory to support just-in-time delivery

Some providers also offer:

Integrated forming and bending

Welding and assembly support

Deburring and edge finishing

Packaging and logistics for ready-to-use delivery

Plasma cutting is built for scale. When you're managing high volumes, material variation, and tight timelines, your cutting process needs to do more than keep up. It needs to drive efficiency at every step.

Whether you’re cutting structural frames, chassis brackets, or protective panels, CNC plasma cutting delivers the speed, precision, and flexibility today’s automotive workflows demand. Ready to scale your automotive builds? Discover how CNC plasma cutting delivers thick steel components – fast, precise, and production-ready.

Bad-fitting panels cost car makers millions. When parts don't line up right, production stops and costs pile up fast. Today's cars need complex panel designs with tighter fits than ever before. This creates big challenges for metal shops using old cutting methods. Laser cutting has changed how these key parts are made. It offers precision that cuts waste, reduces fixes, and speeds up production.

This post shows you how laser cutting creates better automotive panels. You'll learn the benefits of high-powered fiber lasers, discover what affects cut quality, and see how good cutting leads to better forming later on.

Old cutting methods can't meet today's tolerance standards. Mechanical shearing often leaves edges that cause problems during forming. Laser cutting, especially with modern fiber systems, works much better.

High-powered fiber lasers cut car-grade materials with amazing precision. The focused beam makes clean, square edges with minimal heat damage. This edge quality directly affects how panels behave during forming. It's like cutting with sharp scissors instead of dull ones – the cleaner the cut, the better the pieces fit together.

The move to lighter, stronger materials in cars has made precision even more important, as these advanced materials are less forgiving during forming operations.

Steel panels cut with 6,000W or 10,000W fiber lasers offer several clear advantages:

Less Warping - Laser cutting keeps material from distorting. This means panels stay closer to their designed size and shape. The reduced heat input compared to plasma cutting makes a big difference in maintaining part geometry.

Tighter Fits - Modern fiber lasers routinely achieve ±0.1 mm accuracy on automotive materials. Parts that fit better require less force during assembly, reducing wear on fixtures and improving quality.

Cleaner Edges - Laser cutting leaves fewer rough spots compared to plasma cutting. The smooth edge condition improves how material flows during pressing operations.

Less Heat Damage - Limited heat keeps the material's properties intact near cut lines. This matters for high-strength car steels that can lose up to 15% of their strength when overheated.

Edge quality from cutting directly affects how predictably the material will form later. This link between cutting and forming isn't just theory – it directly impacts how efficiently you can make parts.

Not all laser cutting gives the same results. Several key factors determine whether cut panels will form properly later.

The choice between nitrogen and oxygen in laser cutting directly affects edge quality and material performance in later processes. Nitrogen produces cleaner cuts, preventing oxidation and improving formability, but it requires higher pressure and power consumption. Oxygen cuts faster on thicker materials, thanks to its exothermic reaction, but it leaves an oxide layer that may need additional processing.

For automotive panels that require forming, nitrogen is usually the better choice. It creates a smooth, oxide-free edge, allowing for more predictable forming during pressing. However, nitrogen is more expensive, so manufacturers often balance edge quality with cost efficiency. Many shops try to cut costs by using oxygen for all cuts, but high-strength steels and deep-formed parts can experience unpredictable behaviour due to the oxide layer.

The ideal gas pressure depends on material thickness, with thinner sheets requiring lower settings and thicker materials needing higher nitrogen levels or a switch to oxygen. Since materials vary in composition and response to cutting, regular testing helps optimize settings for quality and efficiency.

For a deeper look at how assist gases impact laser cutting performance, check out our guide to the role of assist gases in laser cutting, which explores how nitrogen and oxygen affect cutting quality, efficiency, and cost considerations.

Cutting speed has one of the biggest impacts on edge quality. While faster cutting means more output, excessive speed creates micro-flaws that cause forming failures. For panels that will undergo complex forming, slightly slower cutting often pays off later with fewer downstream issues.

Some fabricators push cutting speeds to maximize throughput. This approach might look good on paper but often leads to quality issues later. The additional time spent fixing forming problems typically exceeds the time saved during cutting.

The right speed depends on the material grade and thickness. Advanced car steels like UHSS (Ultra High-Strength Steel) often need slower cutting speeds than mild steel of the same thickness.

A worn or damaged nozzle greatly reduces cut quality. Regular checks and replacement of nozzles ensure consistent results. Even small nozzle wear can create noticeable differences in edge quality.

Focus position relative to the material surface also affects edge quality. For car panels:

Focus on material surface: Best for medium thickness

Focus slightly below surface: Better for thicker materials

Focus slightly above surface: Can improve thin sheet cutting

Keeping proper focus requires regular calibration and accounting for material variations. Laser machines with auto-focus capabilities help maintain consistent quality across different material thicknesses.

After cutting, several factors influence how well panels will form. Taking these aspects into account leads to better results in the press brake.

Despite laser cutting's clean edge, some car applications need additional edge work. Light deburring removes any remaining rough spots that could cause cracking during forming. For severe forming operations, edge rolling slightly rounds the corners of cut edges, reducing crack risk.

Many operators skip this step, assuming laser-cut edges don't need preparation. This assumption often leads to inconsistent forming results. A quick inspection and light deburring takes minimal time but can prevent costly failures.

Metal sheet has a grain direction from the rolling process that greatly affects forming success. The best approach aligns bends across the grain direction when possible. When complex parts need bends in multiple directions, putting the most severe bends across the grain reduces failure risks.

When forced to form along the grain direction, increasing the inside radius helps reduce cracking and improves forming success. Industry guidelines emphasize that bending with the grain creates a weaker bend, increasing the risk of failure, and that using a larger bend radius can help mitigate these challenges.

By considering grain direction and bend radius adjustments during part layout, manufacturers can significantly improve forming success rates.

How parts are arranged for cutting directly affects material use and part quality. For automotive panels, these strategies help:

Group parts by thickness to reduce setup changes.

Align bends with the material grain, when possible, to improve forming.

Leave space between parts to prevent heat distortion.

Keep key features away from the starting cut to maintain accuracy.

A high-volume fabricator found that upgrading their nesting software significantly reduced material waste and programming time. By arranging parts more efficiently, they cut down on scrap, sped up production, and improved overall quality. These improvements helped them handle more jobs with the same materials, saving costs without sacrificing precision.

Maximizing material use is important, but focusing only on nesting efficiency can cause problems later in forming. The best approach balances material savings with forming needs, ensuring better part quality and smoother production overall.

The car industry keeps evolving, creating new requirements for panel fabrication. Staying ahead of these trends helps shops remain competitive.

Modern vehicles increasingly use mixed materials like aluminum, high-strength steel, and composites. Fiber lasers excel here because they can cut different materials with minimal setup changes. Many shops that previously struggled with multiple cutting systems now handle diverse materials with a single laser machine.

The days of simple, flat panels are disappearing. Today's automotive designs feature complex curves and details that require sophisticated manufacturing. Laser cutting provides the flexibility needed to produce these increasingly complex parts with the precision required for proper assembly.

Integrated systems that move from cutting directly to forming reduce handling damage and improve output. These systems connect cutting data with forming parameters to optimize the entire process.

AI-enhanced monitoring during cutting can predict potential forming problems before they happen. These systems analyze edge conditions and flag parts that might cause issues downstream. Early adopters report significant reductions in quality issues by catching problems before they reach forming operations.

These trends point toward closer integration between cutting and forming, with quality control starting at the cutting stage. Shops that embrace this integration gain advantages in quality, efficiency, and customer satisfaction.

Successful car panel production requires attention to the entire process, starting with cutting. Most production problems show up during forming but start in earlier stages.

Good laser cutting creates the foundation for successful forming. Well-cut panels with clean, consistent edges form more predictably and result in higher-quality finished parts. The investment in proper cutting technology pays dividends throughout the production process.

For shops looking to improve car panel production, examine your cutting processes first. Small adjustments to cutting settings often yield big improvements in forming success. Consider conducting trials with different cutting parameters and measuring the impact on downstream operations.

Ready to see how precision laser cutting can transform your automotive panel production? Contact Amber Steel today for a consultation and discover how our 6,000W and 10,000W fiber laser systems can improve your quality while reducing costs.