We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

If you’re passionate about metal cutting or just keen to learn more, you’ve landed in the right place.

For over 38 years, Amber Steel has been at the forefront of metal cutting services, specializing in laser cutting, flame cutting, and plasma cutting. Our expertise has carved a niche in this cutting-edge industry, delivering precision and excellence across industrial projects big and small.

In our blog, we’ll share a mix of useful tips, innovative applications, our thoughts on sustainability in steel cutting, and more. Expect stories from the cutting floor, insights into how our processes can streamline projects across industries, and a few lessons we’ve learned along the way.

While we keep some of our trade secrets under wraps, this blog is designed to offer valuable nuggets of wisdom that you simply won't find anywhere else. Whether you’re a professional in the industry or someone fascinated by the possibilities of metal cutting, you'll find something of value here.

So, stick with us as we delve into the finer points of metal work. We’re glad to share our insights and lead discussions that matter to our industry.

How precision metal cutting propels the aerospace industry, from constructing lighter frames to enhancing aerodynamics.

The role of advanced metal cutting in automotive manufacturing, driving innovations in vehicle design and efficiency.

All about the robust and versatile process of flame cutting, ideal for tackling thicker metals with precision and ease.

Discover the art of crafting metal furniture, where cutting techniques meet design to create both functional and aesthetic pieces.

A behind-the-scenes look at the mechanics of metal cutting technologies and the science that makes them tick.

Laser cutting is where extreme precision meets efficiency, allowing for intricate designs and clean finishes.

The critical role of precise steel cutting in developing reliable and intricate medical devices.

How steel cutting supports the oil and gas industry with components that withstand extreme environments and pressures.

Known for its speed and versatility, plasma cutting slices through conductive metals with hot plasma.

Safety first! Tips and insights on maintaining a safe environment while handling powerful metal cutting equipment.

The backbone of construction, where steel fabrication and cutting technologies create frameworks that shape skylines.

Sustainability

A look at sustainability in metal cutting, focusing on practices that reduce waste and conserve energy to protect our planet.

In fabrication, the true cost of a mistake doesn’t always show up right away. A slightly uneven kerf or a cut edge just a bit off might seem minor, but once that part reaches assembly, the problem often grows.

Suddenly, you’re facing delays, rework, or even scrapped components. These aren’t small issues—they waste time, raise material costs, and disrupt every phase that follows. That’s why precision cutting matters.

When cuts are clean and consistent from the start, the rest of the process runs more smoothly. Parts fit the way they should, operators spend less time fixing mistakes, and timelines are easier to keep. Fewer surprises means fewer setbacks.

Smooth production helps avoid the ripple effect of delays that creep into forming, welding, finishing, or final assembly. The result is better labour efficiency, tighter cost control, and more predictable outcomes.

Rework doesn’t just add a few minutes—it sets off a chain reaction. A slightly off-spec part might need grinding, welding, or machining just to be usable. That pulls workers off primary tasks, delays other jobs, and consumes more material than expected.

These disruptions rarely happen in isolation. When parts don’t fit, production lines stall. Project managers scramble to adjust schedules or even halt assembly until replacements are cut. A single error quickly multiplies across the job.

For manufacturers, these fixes quietly reduce margins. They stretch timelines, use up labour, and sometimes lead to missed deliveries or rejected parts. It also affects morale, with skilled workers stuck fixing avoidable mistakes. Instead of building, they end up correcting.

That’s why more fabricators are making cutting accuracy a priority. Reducing variation at the start helps eliminate issues later. It’s a simple equation: better cuts lead to fewer problems.

Precision cutting isn’t just about having better equipment. It’s about using that equipment with accuracy and consistency. Standard machines can get the job done, but they often introduce variation. A slight burr, a wider kerf, or a misaligned feature can be enough to throw a part out of spec.

Precision setups minimize that risk. Whether it’s laser, plasma, or waterjet, the goal is consistent accuracy. These machines are calibrated to hold tight tolerances across both simple and complex cuts, even through long production runs.

That’s where the benefits add up. Clean edges, minimal burrs, and precise hole placement reduce scrap and simplify the next step. When parts move smoothly into welding, forming, or assembly, production stays on track.

Take a steel bracket headed for welding. If the holes are even slightly off, extra grinding or clamping might be needed just to make it fit. With precision cutting, that bracket arrives accurate and ready to install.

It’s not just about edge quality. It’s about cutting risk, saving time, and keeping the entire process moving efficiently.

When a part isn’t cut correctly, it sets off a chain reaction. Assembly slows down, welding becomes more difficult, and quality control ends up flagging issues that could have been avoided. Small errors early on can ripple through the entire job.

Cutting parts to spec from the beginning helps everything fit as intended. Welders focus on their actual work instead of fixing flaws. Assemblers spend less time realigning components. Teams avoid last-minute adjustments that throw off the schedule.

Precision cutting also makes the workspace safer. When operators don’t have to grind or fix edges, they’re exposed to fewer hazards like sparks, debris, and repetitive motion strain.

Material handling becomes easier, too. Clean, accurate cuts reduce sharp edges and help prevent warping, making parts safer to move through forming or finishing without damage. In short, better cuts lead to better flow.

It’s like building on a solid foundation. When the base is level and true, every step that follows runs more smoothly. Precision cutting sets that foundation from the very first move.

Choosing the right cutting process isn’t just about preference. It’s about matching the method to the performance requirements of the job.

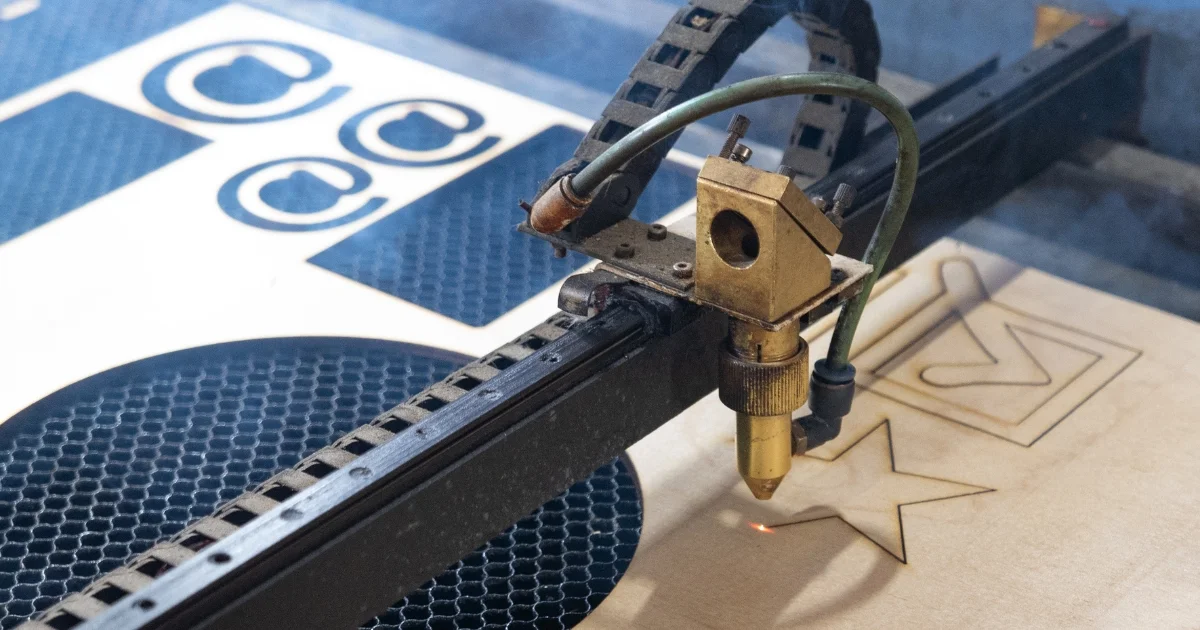

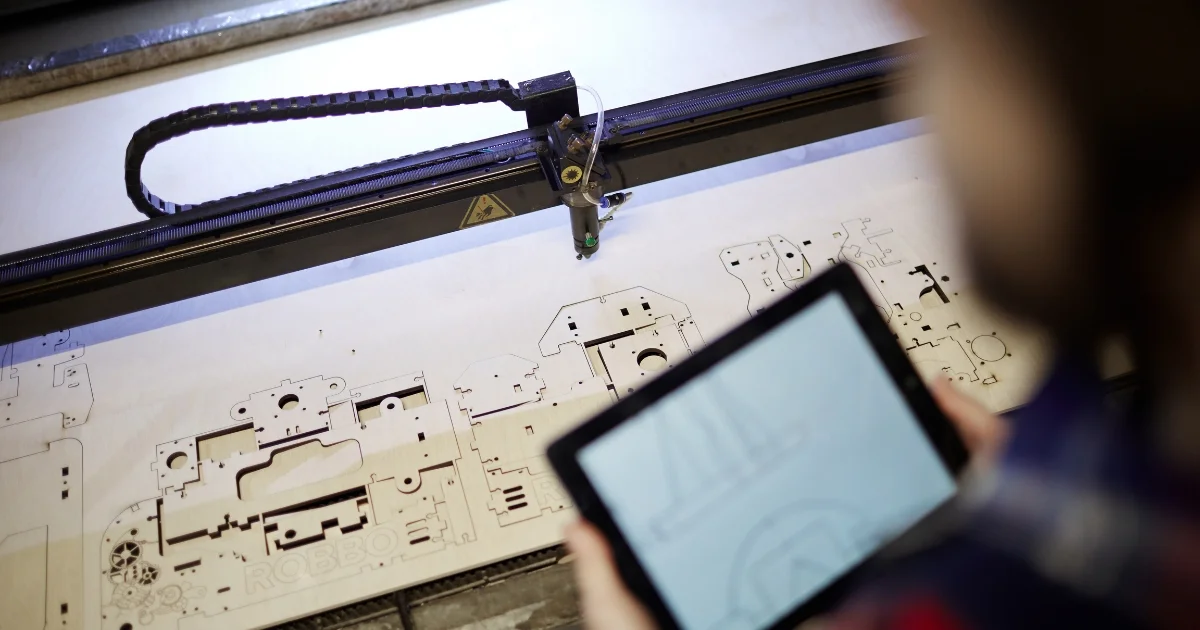

Laser cutting delivers exceptional precision with clean lines and tight tolerances. It’s especially valuable for thin to medium materials used in industries like aerospace and medical devices, where consistency and edge quality are critical. With heat-affected zones as small as 0.1mm and tolerances down to ±0.003", laser systems provide excellent control for complex parts.

Plasma cutting is ideal when speed and cost-effectiveness are priorities. It works well with medium to thick materials, up to 1.250", commonly used in construction, mining equipment, and industrial machinery. Modern high-definition systems can hold tolerances around ±0.040", making plasma a strong choice for large-scale projects that demand both speed and accuracy.

Flame cutting remains the most practical option for very thick steel plate, from 2" up to 12". It’s commonly used for structural steel, shipbuilding, and oil and gas components. Although the heat-affected zone is wider than with other methods, careful control helps maintain cut quality and reduce distortion, even on large profiles.

Each cutting method has specific advantages. The key is selecting the one that aligns with the material type, thickness, and overall fabrication goals.

It’s one thing to cut a part accurately. It’s another to design that part in a way that makes precise cutting possible in the first place.

That’s where Design for Manufacturability (DFM) comes into play. When engineers plan for the cutting process from the start, instead of after the fact, it helps prevent the issues that often lead to delays or rework.

Here are a few simple but critical strategies:

Avoid tight internal corners that are difficult to machine or cut cleanly.

Space holes and features far enough apart to reduce the risk of distortion.

Account for kerf width, especially when transitioning between laser, plasma, or flame cutting methods.

Take a steel gusset plate, for example. A sharp 90-degree internal corner might seem like a clean solution on paper, but in reality, it creates stress concentrations and cutting challenges. Adding even a small radius, such as 0.125", can reduce risk and extend the lifespan of the part.

Today’s precision cutting is no longer just mechanical. It’s becoming increasingly intelligent. Modern monitoring systems now track cut quality in real time, alerting operators to potential issues like overheating, nozzle degradation, or inconsistent speeds. These alerts help catch problems early, before they impact entire production runs.

Artificial intelligence is taking this a step further. AI-driven platforms automatically adjust cutting parameters based on live data, fine-tuning speed, power, and gas pressure to maintain consistent quality, even when material properties fluctuate.

This kind of automation is especially valuable in high-stakes industries like aerospace, where even one rejected part can cost thousands. Manufacturers using AI-driven tools have seen up to 40% gains in overall efficiency, helping reduce delays, improve precision, and minimize costly errors.

And this technology is no longer reserved for large-scale operations. As prices fall and software improves, smaller fabrication shops are beginning to adopt these tools as well. The result is more consistent outcomes and fewer production issues—without the need for oversized budgets or dedicated automation teams.

Not every part demands ultra-tight tolerances, but when precision matters, there’s no substitute for a clean, accurate cut.

Precision cutting services are especially valuable in projects where:

The material is costly, rare, or difficult to replace

The part requires tight fit-up or minimal weld prep

The application involves regulated standards or traceability

The timeline is tight, and mistakes come with high penalties

Industries like defense, electronics, medical, and transportation often fall into this category. In these environments, even a small dimensional error can cause major setbacks—or worse, complete part rejection.

Precision cutting helps eliminate that risk. It improves part quality, reduces scrap, and keeps teams focused on progress rather than corrections. When you know your parts will arrive ready to assemble, there’s no need to pad your schedule or overcompensate in later stages. You can move forward with confidence.

When the cost of a bad part is high, a well-cut one becomes far more than a line item. In these cases, precision is not an upgrade—it’s a requirement.

Cutting may happen early in fabrication, but it affects every step that follows. If the cut is off, delays spread quickly. If it’s clean and accurate, the rest of the job stays on track.

That’s why cutting accuracy is one of the smartest places to invest. It reduces downstream problems, protects your schedule, and keeps production focused on building—not correcting mistakes.

In high-pressure environments with tight deadlines, costly materials, or complex assemblies, there’s no room for error. Precision cutting services from the start help prevent problems before they begin.

Need precision without the rework? Contact us to request a quote or talk to a fabrication expert about your next project. Our team delivers clean, consistent cuts tailored to your specs—every time.

Anyone who's spent time in fabrication knows one truth: your cut defines your project. When you're transforming raw metal into something extraordinary—whether it's a building that will touch the sky or a machine part with micron-level precision—how you make that first cut is make-or-break. It's not about brute force; it's about understanding how every millimetre matters.

But here’s the thing: not all cutting methods are the same. Laser cutting delivers unmatched precision for detailed designs. Plasma cutting is fast and handles thicker materials with ease. And for heavy-duty work, flame cutting is the go-to option. The key is knowing which method is right for your project. Make the wrong choice, and you’re looking at wasted time, resources, and possibly a lot of frustration.

In this guide, we’ll break down the most common cutting processes, how they work, and where they shine. By the end, you’ll have the clarity you need to pick the best approach for your next project. After all, when you start with the right cut, everything else falls into place.

Metal cutting is an important step in transforming raw materials into components used across countless industries. Whether it’s shaping steel beams for construction or crafting intricate machine parts, the cutting process ensures everything fits together and functions as intended. Precision is key here—without it, assembly can become a challenge, leading to delays or even failures.

Different projects call for different cutting methods. Laser cutting offers unmatched precision for detailed work, while plasma cutting is better suited for thicker materials. Flame cutting, on the other hand, excels in heavy-duty applications. Each method has its place and understanding when to use which can make all the difference in achieving efficiency and cost-effectiveness. Learn more about the basics of metal cutting here.

Laser cutting uses a concentrated beam of light to heat and melt the material at specific points, creating clean and precise cuts. A jet of gas then removes the molten material, leaving behind a smooth edge.

Strengths: Laser cutting is renowned for its precision, capable of creating intricate designs with tolerances as tight as ±0.005 inches. The smooth edges it produces often eliminate the need for post-processing, saving time and effort. It’s ideal for thin materials and detailed projects.

Limitations: Laser cutting struggles with thicker materials, where the process becomes slower and more expensive due to increased energy requirements. The upfront cost of laser cutting equipment also makes it less practical for smaller or less precise jobs.

Plasma cutting uses a high-temperature ionized gas to melt and remove metal. The plasma jet is formed by forcing gas through a nozzle while applying an electrical arc to ionize it.

Strengths: Plasma cutting is versatile, capable of cutting through metals up to 1.5 inches thick. It’s faster than laser cutting for these applications and is suitable for a wide range of materials.

Limitations: While fast, plasma cutting produces rougher edges compared to laser cutting, often requiring additional finishing. Its precision is also lower, making it less suitable for intricate designs.

Flame Cutting: Heavy-Duty Power

Flame cutting uses a mixture of oxygen and fuel gas to create a flame hot enough to melt metal, which is then blown away by the oxygen jet.

Strengths: This method is ideal for cutting thick steel, often exceeding 1 inch. It’s a cost-effective solution for heavy-duty jobs, especially in industries like construction and shipbuilding.

Limitations: Flame cutting produces a heat-affected zone (HAZ), which can warp the metal or alter its properties. It also has lower precision than laser or plasma cutting, making it unsuitable for projects requiring tight tolerances.

Understanding these methods and their strengths and limitations is the first step in selecting the best process for your project. Each method has its place, and choosing wisely ensures better results and fewer complications down the line.

Choosing the right cutting process is like choosing the right tool for a job—it depends on what you’re working with and what you need to accomplish. The right decision can save time, money, and effort, while the wrong one can lead to frustration and wasted resources.

Thin materials like sheet metal or aluminum are ideal for laser cutting, which provides precision and clean edges.

Plasma cutting handles metals up to 1.5 inches thick efficiently.

Flame cutting excels for steel plates over an inch thick, cutting dense materials with ease.

High-tolerance industries (e.g., aerospace, automotive) require laser cutting for exact fits.

Structural projects (e.g., beams, frames) allow for looser tolerances, making plasma or flame cutting more practical.

Laser cutting is a higher upfront investment but minimizes rework costs.

Flame cutting is budget-friendly but may require finishing work.

Plasma and flame cutting are faster options for projects with tight timelines.

Laser cutting may take longer but produces more precise results, reducing errors.

By evaluating these factors, you can choose a cutting method that aligns best with your needs.

Each cutting method has its pros and cons. Understanding these trade-offs can help you make the right decision.

Advantages: Exceptional precision, minimal finishing, ideal for intricate designs.

Disadvantages: Struggles with thick materials; higher upfront cost.

Advantages: Fast, versatile, handles thick materials.

Disadvantages: Rougher edges; less suitable for detailed projects.

Advantages: Cost-effective, great for thick steel.

Disadvantages: Lower precision; heat-affected zones may require rework.

For a comprehensive comparison of laser, plasma, and flame cutting technologies, check out Making Sense of Metal Cutting Technologies by The Fabricator.

Every cutting method has its place, and choosing the right one depends on the specific demands of the industry. Some projects require extreme precision, while others call for speed and durability. Here’s how laser, plasma, and flame cutting are commonly used in different fields.

Automotive Industry: Laser cutting for engine parts, gears, and brackets.

Construction: Plasma and flame cutting for steel beams and large-scale jobs.

Aerospace: Laser cutting for lightweight, high-precision components.

Manufacturing: Plasma cutting for general-purpose parts and equipment.

Equipment Limitations: Machines require maintenance and calibration.

Material Behavior: How different metals respond to heat and cutting methods.

Balancing Cost and Precision: Avoid overengineering for unnecessary precision or sacrificing quality to save money.

Production Bottlenecks: Inspections and finishing work can slow timelines.

Getting the right balance between precision and efficiency is one of the toughest parts of metal fabrication. Push for perfection, and you’ll overspend and slow down production. Relax the standards too much, and you risk ending up with parts that don’t fit or function properly. The trick is knowing when accuracy matters most and when it’s okay to let go a bit.

Not every part needs perfect precision. Take structural steel beams, for instance. As long as they’re close to the required dimensions, small variations won’t cause any problems. But for something like bolt holes, there's no room for mistakes. They need to be spot-on for everything to line up during assembly. Focusing your precision where it really counts helps you avoid wasting resources on perfection that doesn’t matter.

It’s tempting to demand the highest tolerances for every cut, but this often leads to wasted time and money. Tight tolerances need advanced tools, slower cutting speeds, and extra inspections—all of which can quickly add up. If your project doesn’t require laser-sharp accuracy, looser tolerances can do the job just as well and keep your costs in check.

Mixing cutting methods is one smart way to balance precision and efficiency. Use laser cutting for intricate details that need tight tolerances, and plasma cutting for larger, simpler pieces. This hybrid approach lets you take advantage of the strengths of each method, speeding up production while still ensuring quality where it counts most.

At the end of the day, balancing precision with efficiency isn’t about cutting corners; it’s about making smart decisions. By matching your approach to your project’s needs, you save time, keep costs under control, and still get the results you want without complicating things.

Every project starts with a choice, and in metal fabrication, that choice is the cutting process. It’s not just about slicing through steel or aluminum—it’s about making sure every cut serves the bigger picture. Whether it’s the clean precision of laser cutting, the speed and versatility of plasma cutting, or the brute power of flame cutting, the method you choose shapes everything that comes next.

Laser cutting is perfect when precision is key, especially in industries like aerospace or automotive, where every detail counts. Plasma cutting, on the other hand, gives you the flexibility and speed needed for thicker materials, making it a go-to in construction and general manufacturing. And when it comes to heavy-duty work? Flame cutting steps in, where power takes precedence over perfect edges.

The trick to success is balance. Not every part of your project needs the highest precision, and not every budget can stretch to the top tools. By understanding what your project truly needs—whether it’s speed, accuracy, or cost—you can choose the method that’s right for the job.

Ultimately, metal cutting is about more than just shaping materials. It’s about creating something that works, lasts, and fits the bigger picture. Choose wisely, and each cut will bring you closer to a project you can truly be proud of.

Ready to start your next project? Contact Amber Steel for expert advice and cutting solutions.