We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

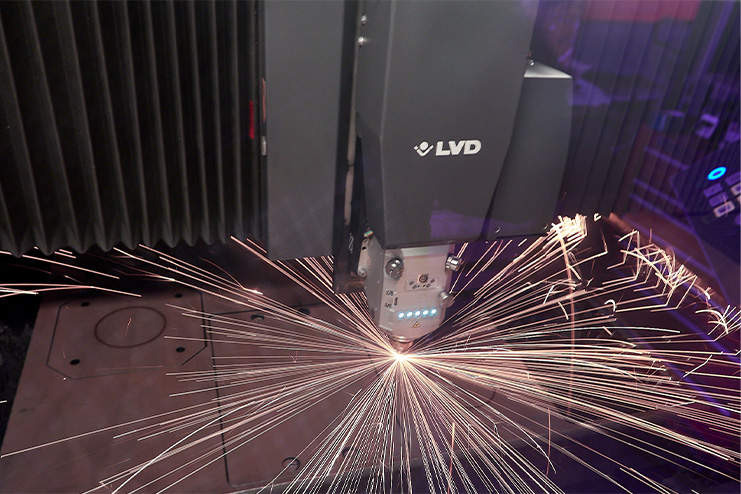

Laser cutting is an advanced technology used to precisely cut various materials, including metals like steel. It works by using a powerful and focused beam of light, called a laser, to melt or vaporize the material along a specific path. This precise method allows for intricate and detailed cuts that might be difficult to achieve with traditional tools.

Laser cutting is widely used in industries like manufacturing, automotive, and electronics, as it offers high levels of accuracy, speed, and versatility. It's a remarkable process that showcases the fusion of cutting-edge technology and skilled craftsmanship in the world of material fabrication.

Since 1986, Amber Steel has led the industry in laser, plasma, and flame cutting. Serving within 100 km of Waterloo Region, we deliver precise, ready-for-production parts primarily for the mining, automotive, construction, and technology sectors.

Learn More About Our Laser Cutting Technology and Capabilities

Our advanced laser cutting technology ensures precise, intricate cuts for all your needs. Contact your steel cutting experts at Amber Steel to bring your project to life! Call us to discuss your laser cutting project, or email us with the details of your design.

At Amber Steel, we are big believers in innovation. Because of this, we have invested ample time and resources into getting state-of-the-art laser cutting technology. Our two laser machines (6,000 watt and 10,000 watt) can meet all design specifications and customer needs.

Laser cutting is a high technological process, ensuring the fastest cutting time, which helps reduce project wait time and presents our customers with a finished product which doesn’t need any further finessing. It goes from our hands right into their assembly line.

Other significant advantages of laser cutting include:

Laser Cutting

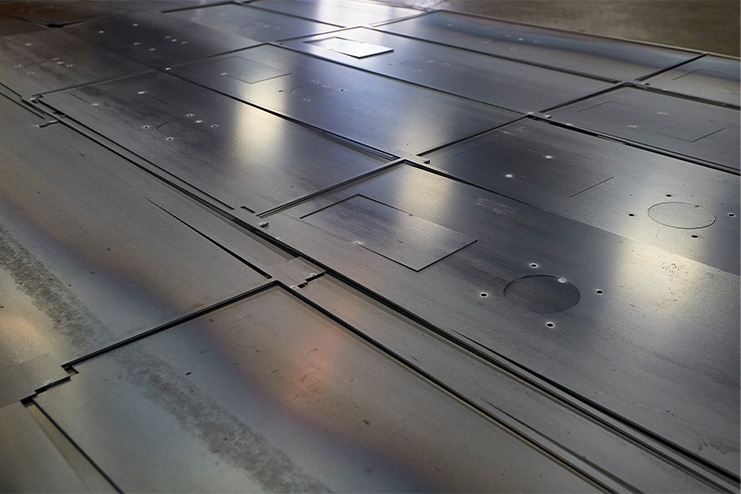

All materials common in industrial processing – from steel to aluminum to stainless steel. Very different sheet thicknesses of 0.5 to 25.4 millimeters thick can be cut using the tool.

This extremely wide material range makes the laser the top cutting tool for many applications in the area of metals.

Laser Cutting

The bundled laser beam only heats up the material locally, and the rest of the workpiece is subjected to minimal thermal stresses or not at all. This means the kerf is barely wider than the beam and even complex, intricate contours may be cut smoothly and free of burrs.

Time-consuming post-processing is no longer necessary in most cases. Due to its flexibility, this cutting procedure is often used for small lot sizes, large variant ranges, and in prototype construction.

Why choose Amber Steel? The answer is simpler than you might think!

We are one of the few steel cutting and manufacturing companies that carry a 72” wide laser. This means that we are not limited to size and can use more of the metal sheet. This allows us to offer a wide range of product sizes for all industries.

Laser cutting is a versatile and precise technology that offers a range of benefits, making it an ideal choice for various industries and applications. Here’s how:

Precision: Laser cutting offers exceptional accuracy, allowing for intricate and detailed cuts.

Precision: Laser cutting offers exceptional accuracy, allowing for intricate and detailed cuts.

Versatility: It can be used on carbon steel, stainless and aluminum Clean Cuts: The process results in minimal material distortion and clean edges, reducing the need for additional finishing.

Versatility: It can be used on carbon steel, stainless and aluminum Clean Cuts: The process results in minimal material distortion and clean edges, reducing the need for additional finishing.

Narrow Kerf: The laser beam is very thin, leading to minimal wasted material and maximizing material utilization.

Narrow Kerf: The laser beam is very thin, leading to minimal wasted material and maximizing material utilization.

Complex Shapes: Laser cutting easily handles complex shapes that might be challenging with traditional methods.

Speed: The process is faster than many traditional cutting methods, enhancing production efficiency.

Speed: The process is faster than many traditional cutting methods, enhancing production efficiency.

Minimal Contact: Laser cutting is a non-contact process, reducing the risk of material contamination.

Minimal Contact: Laser cutting is a non-contact process, reducing the risk of material contamination.

Less Heat Affected Zone: The heat-affected zone around the cut is smaller, minimizing material distortion and warping.

Less Heat Affected Zone: The heat-affected zone around the cut is smaller, minimizing material distortion and warping.

Reduced Setup Time: Quick setup and programming save time during production changes.

Reduced Setup Time: Quick setup and programming save time during production changes.

Automation: Laser cutting can be integrated with automation systems for continuous and consistent production.

Automation: Laser cutting can be integrated with automation systems for continuous and consistent production.

Cost-Efficient: While initial investment may be higher, laser cutting's efficiency, reduced material waste, and low maintenance can lead to cost savings in the long run.

Cost-Efficient: While initial investment may be higher, laser cutting's efficiency, reduced material waste, and low maintenance can lead to cost savings in the long run.

Intricate Designs: Laser cutting allows for intricate designs and patterns, making it ideal for customization.

Intricate Designs: Laser cutting allows for intricate designs and patterns, making it ideal for customization.

Environmentally Friendly: The process generates minimal waste and doesn't require coolants or lubricants.

Environmentally Friendly: The process generates minimal waste and doesn't require coolants or lubricants.

No Tool Wear: Laser cutting doesn't involve physical tools, eliminating wear and tear associated with traditional cutting methods.

No Tool Wear: Laser cutting doesn't involve physical tools, eliminating wear and tear associated with traditional cutting methods.

Laser cutting technology is widely used across various industries due to its precision, efficiency, and versatility.

Some key industries include:

Amber Steel specializes in providing laser cutting services to these and other industries, ensuring high-quality and ready-for-production parts.

Ready to bring your project to life? Let's collaborate and make it happen! Whether you're envisioning a custom metal creation, a precision-cut design, or a specialized fabrication, we're here to turn your ideas into reality. Our skilled team and cutting-edge technology are prepared to tackle projects of all scales and complexities. From initial concept to final production, we pride ourselves on delivering excellence at every step. Let's work hand in hand to bring your vision to reality. Contact us today to discuss your project, receive a tailored quote, and begin working together.